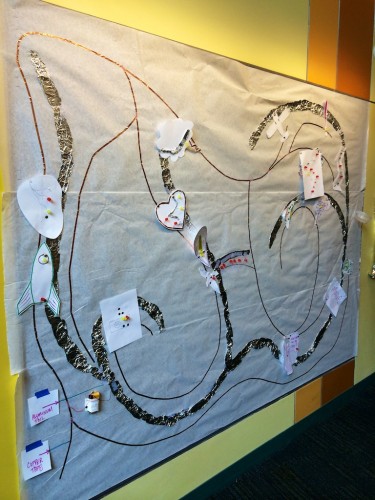

This year at Maker Faire, the Nueva I-Lab team and I pulled out my favorite trusty, easy-to-prep maker activity to offer at our school’s booth. We joked that essentially, we were asking visitors who stopped by our booth to build our sign for us as the Faire went on. 🙂

Many parents and teachers who came by asked about how to do this activity back home, so here’s my very quick set of notes:

Prep

Prepping for this activity took maybe an hour or so. First, you have to plan out what design you want to use as your mural backing – I kept it simple with spelling out our school’s name.

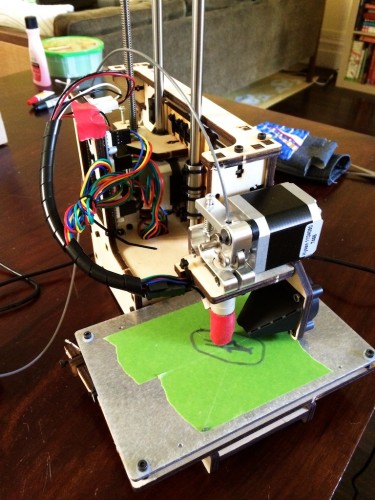

Then you have to plan out how you will lay down parallel positive and negative tracks that follow this design. For letters like U, V, and N, this was pretty easy. For letters like E and A, you have to plan strategically and be prepared to use non-conductive tape like Scotch tape, masking tape, or electrical tape (which is actually not conductive despite its confusing name) to insulate junctions to prevent short circuits. If that last sentence made zero sense, choose an easy design like U, V, N, (or C, D, I, J, L, M, O, S, W, Z) for your first go. You can sort of see how I laid out my letters in this photo:

Once you have planned it out, sketch out your plan on your mural backing surface in pencil, so you have something to follow as you are laying down the copper tape.

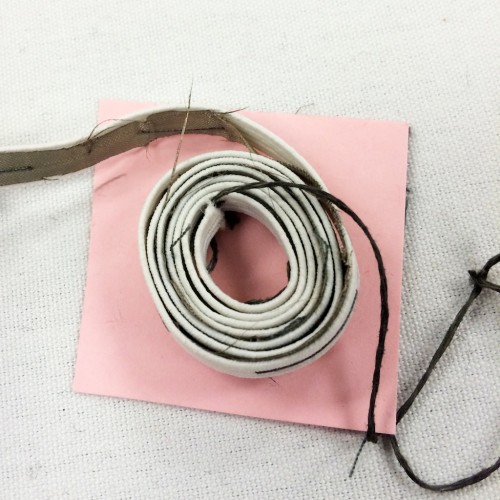

Then you will apply the copper tape to create the two parallel tracks. I usually use a thicker piece of tape for the positive track and a thinner piece of tape for the negative track – this is only for aesthetic (and remembering) purposes because the tape will conduct electricity just fine however wide it is. Try not to break the tape to round corners and instead use a folding technique. (The always-wonderful Jie Qi has some great tips about how to round corners without tearing the copper tape.) If you have to connect two separate pieces of copper tape, I usually assume the adhesive side is not conductive and do a fold-under, followed by another piece of tape on top to secure, to make sure the shiny sides are in contact. (Again, Jie Qi has great tips for this too.)

Once you have finished creating the design, figure out where you want to place the battery pack. Place the red wire in contact with the thicker copper tape track on the mural backing and place the black wire in contact with the thinner one. You may need to strip the two wires from the battery pack to expose more wire. Secure with tape and/or thumbtacks. If you want to get fancy, you can even solder these wires onto the copper tape surface. Anything to make a strong electrical connection. You will also need a way to mount the battery pack – Velcro works well but so does a loop of duct tape or even a giant clip of some sort.

Grab a plain LED and test out your mural backing to make sure it’s getting power (remembering that LEDs have a positive and negative leg, so if it doesn’t light up right away, flip it around and test again), and then you are good to go

Supplies

Here’s the list of stuff I usually buy for this activity – for something like Maker Faire which is about 2.5 days of a constant stream of visitors, I think we went through about 200-300 LEDs (a small number of the packs will be defective).

- Fast cycling LEDs – these wonderful LEDs are already built to cycle through different colors without extra logic or coding. Sparkfun and Adafruit sell these but lately, I have preferred to order them from Amazon in bags of 100. I recommend the fast cycling versus the slow cycling because they are much more “blinky!”

- Two-AA battery packs and AA batteries: The LEDs above run on about 3V, so you will need battery packs that hold two AA batteries. Get the packs with on/off switches so it’s easy for you to cut power to the whole mural at once.

- Copper tape: The width of the copper tape has no bearing on its function. But I generally prefer to buy a roll or two of the 1-inch wide copper tape for creating the mural backing. I also buy many more rolls of the more normal 1/4-inch wide copper tape, which is what kids will use to create their pieces before adding to the mural. Pro tip I learned from a 6th grade colleague at my previous school: To avoid a messy tangle of tape falling off the roll literally 5 seconds after the activity starts, pre-cut short strips of tape so kids just grab from these for their project.

- Paper surface: If you are doing this at your school, you can easily just layer some butcher paper or poster paper on top of an existing bulletin board and then create your mural backing directly on it. I am personally a fan of this black railroad board (blinky lights stand out well against a dark background) but really any surface will do.

- Thumb tacks: While I hate old-school thumb tacks as much as the next person because they are so hard to pry off, they work really well for this project because they are usually also conductive and so can help with making an electrical connection between the mural backing and the mural pieces on top.

- (Optional) Cork/foam boards: Because we were doing this at Maker Faire, we needed a portable version of a bulletin-board-like surface. I used to use plain foam core but found that thumb tacks don’t stay in very well. After many iterations of this project, the best solution I’ve found so far is these cork-lined foam core boards. For some reason, they have gotten more and more expensive, so again, if you have a bulletin board to do this at your school, then please skip this step. Otherwise, it’s $$$ but at least you can reuse these for years to come.

- Craft supplies: I prefer to keep things simple in this category and just limit it to fun papers, markers, scissors, Scotch tape, and glue sticks (not hot glues since that would be a nightmare to supervise at an event like Maker Faire). For paper, I love love love to buy packs of scrapbook paper – Colorbok is a major brand and Amazon sell 12″x12″ or 8.5″x11″ pads of these in a bazillion fun patterns for very reasonable prices. I usually just get whatever is cheapest. Regular old construction paper is also a great standby. I also recently found out there are these construction paper packs that have pre-scored shapes on them — great for very little kids who may have trouble using scissors. If you want to offer more crafting choices, pom poms would be a great addition. But remember to avoid anything that might have conductive materials such as pipe cleaners, glittery materials, ribbons with metallic threads, etc.

The Activity

Once you are prepped and have all the supplies, let the fun begin! I filmed an instructional video for what your participants would have to do, so that’s probably the easiest way to explain it.